A customer (Advanced Hydraulics Inc.) has approached us about some “forensic engineering.” Given

your recent exposure to this customer’s products through your design work, I thought you might be able

to address some of the issues raised here.

Advanced Hydraulics has had three failures in similar manners of identical hydraulic presses after

about 10 years of service life. On one occasion, the failed cylinder was repaired by welding and

returned to the service with no detailed investigation. However, examination of the failures of the

second and third cylinders indicated similar types of failure.

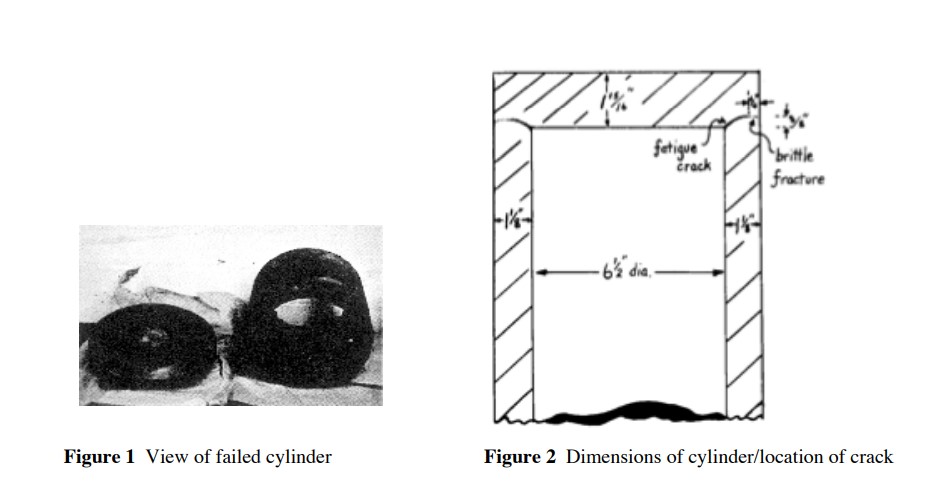

Each fractured cylinder was closed by a flat head as shown in Fig. 1. Pertinent dimensions and

locations of the cracks leading to fracture are shown in Fig. 2. Appearance of the internal surface of

the head and the fracture are shown in Fig. 3.

Specifics of the cylinder and its operation are as follows: The cylinder was a steel casting with a

Brinell hardness of 163 (equivalent to a tensile strength of 79,920 psi). The material is assumed to

have a yield strength of 44,800 psi. Microstructural analysis indicated a carbon content of 0.3-0.4% and

did not reveal the presence of any significant inclusions or segregates which might have contributed to

failure. Operating conditions consisted of an initial pressure of 750 psi ultimately rising to 4,480 psi.

In your analysis consider both the longitudinal stress due to the pressure vessel stresses and the bending

stresses imposed by the flat, closed end. Consider the effect of the stress concentration at the sharp

corner. Also consider if a fracture mechanics approach to the brittle fracture from the fatigue crack is

reasonable for this material (you will need to find/estimate a value for the fracture toughness of the

material).

Finally, based on your knowledge of fatigue and fracture and proper design for fatigue, a) recommend

remedial action to prevent fracture in other hydraulic cylinders of the same design and material and b)

redesign the cylinder end area to eliminate failures of this sort.

Solution

Hydraulic cylinders are crucial components in various industrial applications, providing the necessary force to perform lifting, pushing, and pulling tasks. Understanding the failure mechanisms of hydraulic cylinders is essential to improve their design, reliability, and maintenance. This process outlines the steps to conduct a comprehensive failure analysis of a hydraulic cylinder.

For Complete Solution and Report, Click the Button below.